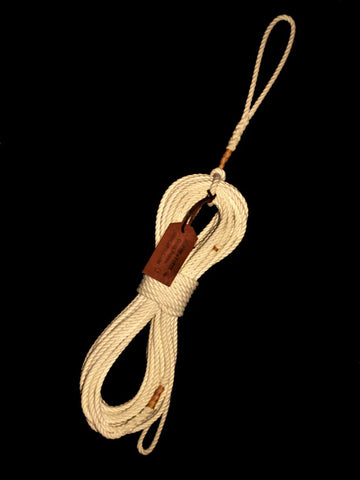

Sounding Leads: Weights & Leadlines

INTRODUCTION

A sounding lead can be used as a primary depth-finding device, or as a backup and calibration device for electronic depth sounders. It is typically attached to a light line which is measured off with bands, tags, knots, or paint markings every fathom or so (known as a 'lead line').

MULTIPLE USES

Sounding leads can be used for position-finding and dead reckoning on coastal passages, or when making landfall from an offshore position. When used in conjunction with GPS and a depth sounder, the peace of mind that comes from being able to verify the accuracy of electronic readings cannot be overstated.

For cruising, sounding leads also offer the advantage of being portable so the exact depth can be checked ahead of time... perhaps from a dinghy. This can be incredibly useful for surveying small creeks, narrow channels, inlets, anchorages, marina slips, and other areas where the exact depth might be uncertain.

THE MANUFACTURING PROCESS

Sounding leads are traditionally manufactured by pouring hot lead into a casting mold. The process itself is low-tech, and no two leads are exactly alike. However some designs are better than others, and we've had these custom made to ensure that each of our sounding leads incorporates the very best and most useful features -

- Octagonal shaped cross-section prevents spinning while deployed. Flat sides can't roll around when placed on deck, or stowed below in a locker.

- Recessed bottom with grooves can be packed with tallow or grease for picking up bottom samples (sand, mud, pebbles, grass, etc.)

- Large, built-in cast eye for attaching leadline rope up to 3/8" diameter

- 3lb weight is suitable for inshore soundings at slow speed, dinghy, etc.

-

7lb weight is recommended for offshore/coastal soundings and navigation

- 100% pure lead - Made in USA